Company Profile

- Experienced Product Development Team

- COTS and Build to Spec

- Critical processes and assemblies performed in-house

- ITAR registered

- AS9100 Rev D registered, initial certification 2007

- IPC J-STD-001 certified soldering technicians, inspectors, and trainers

We establish partnerships with each of our clients and have a proven track record for successfully delivering quality custom power solutions for the world’s most demanding applications.

Since 1992, Aveox has been at the forefront of innovation for brushless DC motor and controller solutions. We serve a diverse clientele, including military, aerospace, medical, commercial, industrial, maritime, space, and automotive. We continually develop and apply innovative motion control technology and Active Power Factor Correction (APFC) to meet our client’s critical performance and environmentally-challenging requirements while achieving and maintaining superior reliability.

Company History

- Founded in 1992

- Designed and manufactured in Simi Valley, CA

- Over 30 years successfully designing and manufacturing brushless DC motors and controllers for mission critical applications

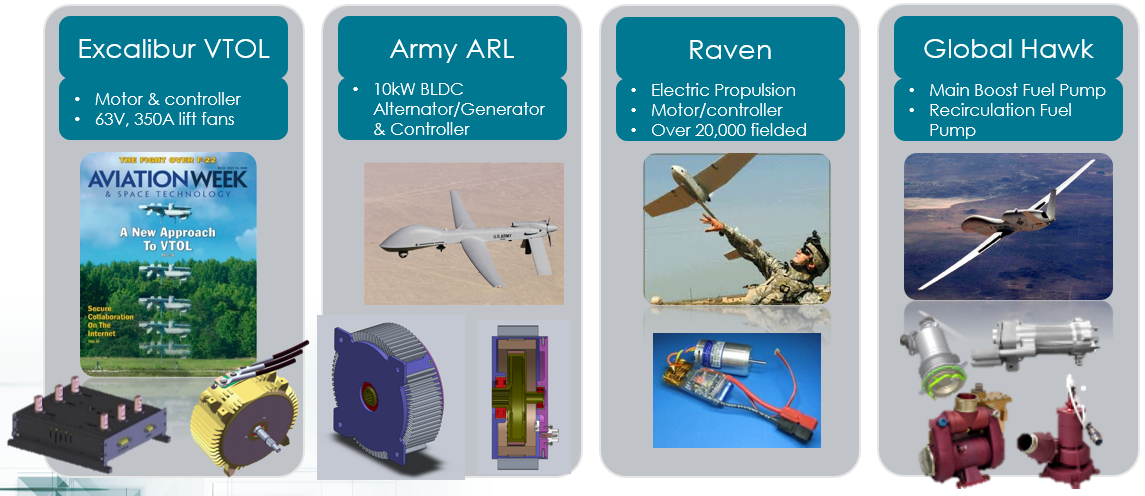

- Pioneer in UAV and UUV (Drone) propulsion components and systems

- Proprietary Technology & Processes associated with AC Power Conversion electronics

- Critical supplier to OEM’s and Top Tier Subcontractors across Military, Commercial Aerospace, Industrial and Medical Markets

MARKETS WE SERVE

At Aveox we cater to all markets, Military and Commercial, where advanced mission-critical electro-mechanical power solutions are required.

PRODUCTS & Applications

Motor Products – COTS Stator/Rotor Sets

Ultimate Torque

- Sinusoidally wound stator/rotor sets

- 1.26” – 9.0” OD

Superior Torque

- Trapezoidal wound stator/rotor sets

- 1.1” – 5.8” OD

Motor Applications

- Gun drive

- Compressor

- Weapon ejection

- ECS

- Fans

- Pumps

- Fuel

- Hydraulic

- Liquid cooling

- UAV propulsion / power generation

- Generators

- Servo

- Antenna Drive

- Missile guidance

- Actuators

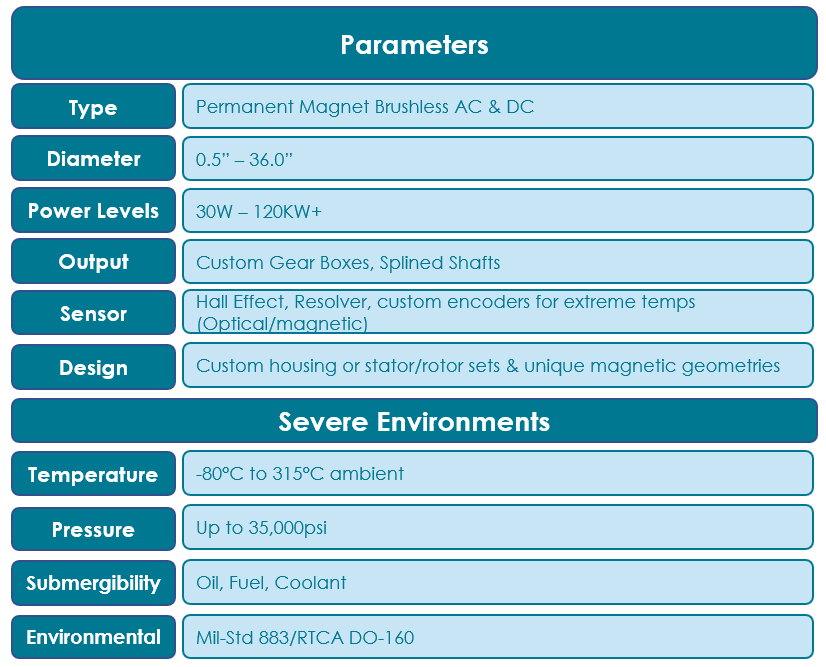

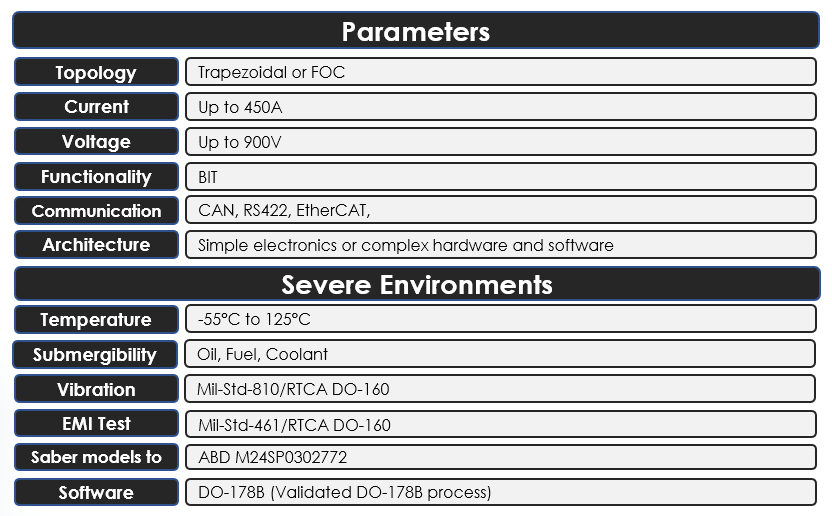

Controller Products

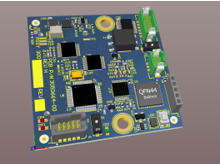

Controller Products – Modular Motor Control (MMC)

Summary of MMC

- 50+ Power Board Configurations, 80V to 800V, 10A to 200A

- Board level to environmentally sealed box with integrated cold plate

- Sensorless FOC controller with Windows GUI

- Analog controller (based on simple electronics)

- EMI filters and AC/DC front ends

Controller Applications

- Pumps/Fans

- Starter/Generator Controller

- Rescue Hoists and Cargo Winches

- Actuators

Active Power Factor Correction (AFPC) Products

Power Conversion Products/Technology

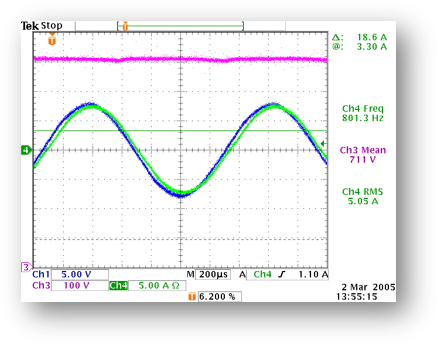

Proprietary 3 Phase Power Conversion with Active Power Factor Correction

- All Analog Control Architecture

- Meets Definition of Simple per DO-254/DO-178)

- Simplified qualification

- High Power Density (light weight ATRU replacement)

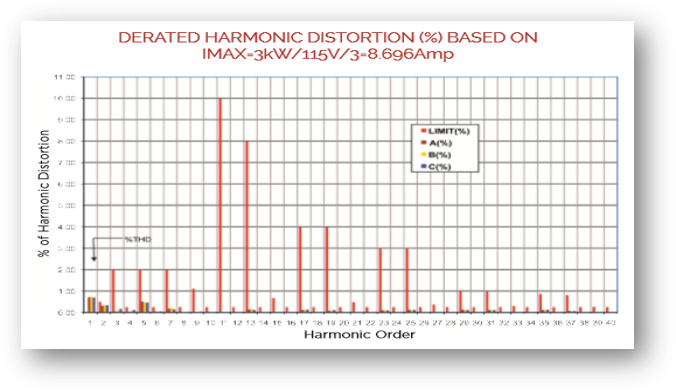

- Ultra-Low Harmonic Distortion (THD <0.7%)

- Chart Illustrates APFC Harmonic Data at 7HP @ 800Hz

APFC Applications

- Three Phase AC Power Supplies

- Motor Controller Front End

- Electronic Warfare/Radar Power Supplies

Unmanned Vehicle (UAV) Applications

Capabilities

Product Development Capabilities

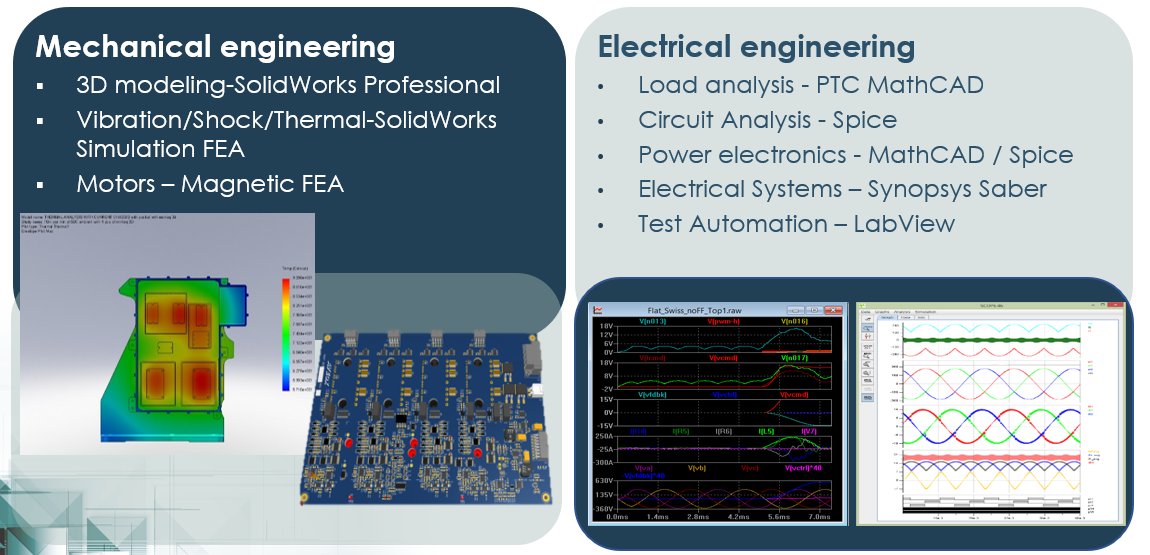

Design Capabilities

- Motor Magnetics & Motor-Gearbox Mechanical

- Multi – Domain Optimization

- Power Electronics

- Embedded Controllers

- Software Development

- Validated processes for DO-178B

- Prototype Assembly & Test

- Reliability safety analysis

- Electronics Packaging Design/Analysis

Simulation Capabilities

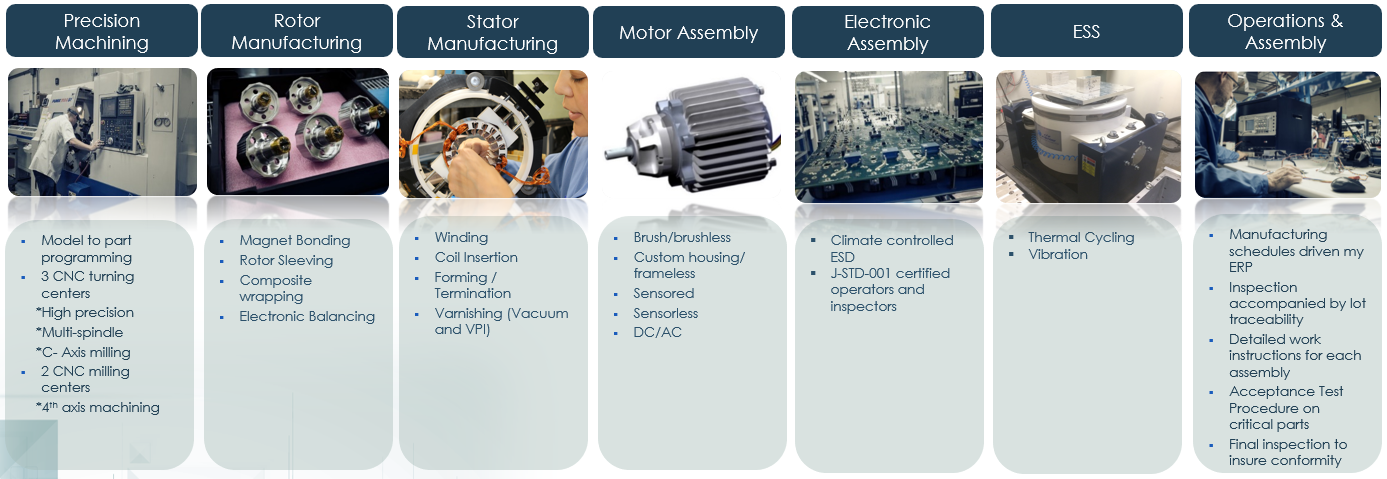

In-House Manufacturing Capabilities

In-House Test Capabilities

Motor

-

- Bonding Resistance

- Insulation Resistance/Dielectric

- Functional Testing

- Dynamometer

- Surge Testing

- Speed

- Torque

- Efficiency

Controller

-

- Bonding Resistance

- Insulation Resistance/Dielectric

- Functional Testing

- Power Quality

- EMI (RTCA-DO-160 & MIL-STD-461 Conducted Emissions)

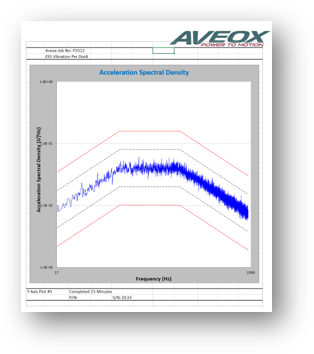

- ESS Thermal

- ESS Vibration

Turnkey – Systems Engineering Approach

Successful Programs & Platforms Served

Boeing 787

Liquid Cooling System

- Power Electronics (PECS), Galley (ICS) & Forward Cargo (FCACS)

- 5.2KW, 230VAC VF 3 Phase Input

- Sensorless Motor Drive with Vienna Rectifier

- CAN Bus Communication

- DO-178B Level B Software

- No Complex Devices

Potable Water Pump

- Sensorless motor controller with Active PFC and Brushless DC Motor Components

- Wet Rotor, Dry Stator

- 115VAC, VF, Single Phase Input

Waste Tank Vacuum Generator

- 8KW Brushless Motor (stator & rotor) and Controller

- 230VAC VF 3 Phase Input

- Sensorless Motor Drive with Vienna Rectifier

- CAN Bus Communication

- DO-178B Level D Software

Motor Drive for Fuel Metering Pump for APU

- Combines functionality of FADAC

- Fuel Pump & metering servo valve

- APU Generator & Battery Power

- Engineered to survive cycling -55C to 125C

- 28V, 70A Peak Current, runs from dedicated

- Space Vector Servo Control

- Acceleration from 1000 to 5000 RPM in 25ms

- DO-178B Level B Software, No Complex Devices

Backup Landing Gear Deployment Pump

- Brushless Motor (stator & rotor) and Controller

- Brushless DC Motor and Resolver Submerged in Skydrol

- Innovative Lightening Protection

- No Software or Complex Hardware

Inflight Wi-Fi Antenna

- Bi-directional Ku/Ka band Satcom ultra low profile

- Direct drive, curved linear motor

- Operating temperature: -55°C to +74°C

- Commutation signals (UVW)

- Temperature sensor

AARGM Missile System

Replaces HARM missile

- Sub-reflector motor for guidance system on Advanced Anti-Radiation Guided Missile (AARGM)

- Gimbal Motor (2x)

- Spin motor

Archerfish UUV

Single Shot Mine Disposal System

- BLDC motor and controller for propulsion

- Mine-seeking expendable neutralizer

- 4 X faster than conventional remotely-controlled mine disposal vehicles

- Selected by NAVSEA as the common neutralizer for use in airborne, shipboard and other applications

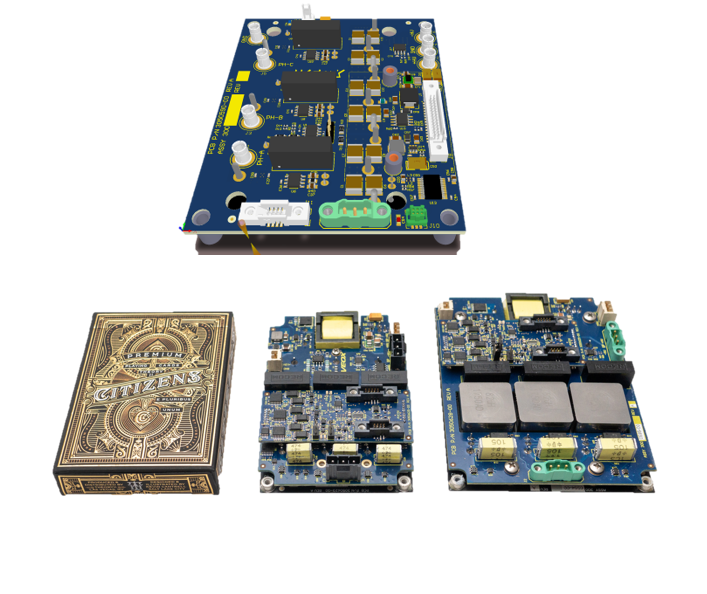

A400M Cargo & Winch Retrieval Winch Controllers

3 Phase PFC & Brushless DC Motor Controller

APFC: Meets Boeing & Airbus current harmonics requirement

Power on Inrush Current Limit

Regen Protection

Input voltage:

3-Phase nominal VRMS = 208 VAC L-L

APFC Output voltage power

350 +/- 25VDC @ 3KW

Motor BLDC controller:

Speed or current control

15Amp Average, 45Amp peak

IGBT Desat Fault detection

SABER Models to ABD M24SP0302772

3 Phase PFC & Brushless DC Motor Controller

APFC: Meets Boeing & Airbus current harmonics requirement

Power on Inrush Current Limit

Regen Protection

Input voltage:

3-Phase nominal VRMS = 208 VAC L-L

APFC Output voltage power

350 +/- 25VDC @ 15KW

Motor BLDC controller:

Speed or current control

30Amp Average, 90Amp peak

IGBT Desat Fault detection

KC-390 Retrieval Winch

Motor

Apache M230 Gun Drive

F-35 Weapons Ejection/Seeker Head Cooling

- Ultra reliable bearing system

- Complex sealing solution

- Designed for extreme temperature, vibration, shock

- Proprietary stator/rotor design

- Specialized housing geometry

MLRS – Multiple Launch Rocket System

- Motor & Controller

- 200A @ 28V Compressor Drive for Environmental Control System (ECS)

Paladin PIM Tank – M109A7

155mm Self-Propelled Howitzer Cannon Artillery System

- Custom controller and brushless DC motor

- Drives the radial & axial fans and compressor for the Microclimate Conditioning System (MCS)

- 610V controller package

- 4 controllers in a common package

- Ruggedized for Road Shock, Gun Firing Shock and Ballistic Shock

F-18

AT-FLIR

Aveox’s custom designed Amplifier Optical & Infrared Spectrum De-Rotation Optics Servo Driver

- Program in full-rate production

- 2 axis high band width current loop used optical mechanism

AC130 Gun Ship – Laser Weapons Cooling

8KW Thee Phase Active PFC & Motor Controller & Motor

- 115VAC, 400HZ, MIL-STD-704 Power

- Sensorless FOC controller running a coolant pump

Currently in Development

25KW Thee Phase Active PFC & Motor Controller

- 440VAC, 60HZ, MIL-STD-1399 Power

- Upgrade of legacy pneumatic powered gun to electric powered

- Currently in Development