Our World-Class Facility is Focused on Quality & Innovation

At AVEOX, our state-of-the-art 20,000 sq. ft. facility reflects our commitment to quality and innovation. Vertically integrated with extensive in-house design, manufacturing and testing capabilities, we ensure excellence at every stage. Our advanced ERP-driven operations streamline processes, from prototyping to full-scale production, optimizing costs while crafting products of superior quality.

Our Facility is:

- Climate Controlled

- ESD Protected

- Designed for Efficiency

Our Processes & Technicians are:

- ISO9001 Certified

- AS9100 Certified

- IPC-J-STD-001 Certified

Located in the heart of Ventura County, California, our facility is easily accessible via the 118 freeway.

AVEOX Capabilities

Engineering

Got a power challenge? Whether you need a semi-custom or full-custom power solution, our team of engineers is here to assist. We excel in:

- Active Power Factor Correction

- Design Assurance Level A

- Customized Electromagnetics

- Electronics Packaging

- Embedded Software (DO-178B & CMMI Level 3)

Modeling & Simulation

Modeling and simulation are crucial for identifying potential issues and optimizing performance, before physical prototypes are built. Our engineers use the latest CAD tools to perform:

- Finite Element Analysis (FEA)

- Computational Fluid Dynamics (CFD)

- Circuit & Electrical Systems Analysis

- Test Automation

Precision Machining

Our experienced machinists utilize advanced tools to precision machine complex parts with intricate angles and contours. Our in-house machine shop features:

- 3 CNC Turning Centers

- 4th Axis Machining

- 2 CNC Milling Centers

- C-Axis Milling

- Multi-Spindle Machining

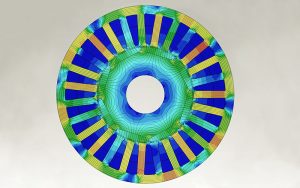

Rotor & Stator Manufacturing

AVEOX specializes in the manufacture of rotors and stators for electric motors. Our in-house technicians expertly perform all key processes such as:

- Magnet Bonding

- Rotor Sleeving

- Composite Wrapping

- Winding & Coil Insertion

- Electronic Balancing

- Encoder and Resolver Calibration

- Vacuum Pressure Impregnation (VPI)

Electronics Assembly

We integrate power control electronics with our motors. Our quality-controlled electronics assembly is:

- Conducted in Climate-Controlled, ESD-Protected Environments

- Performed by J-STD-001 Certified Technicians

- Enhanced with Conformal Coating

- Supported by Parts from AS9100, ISO9001, NAD-CAP-Certified Suppliers

Motor Testing

Our in-house functional testing capabilities ensure each motor we build meets all regulatory compliance and design criteria. Our protocols include:

- Bonding Resistance Tests

- Dielectric / Insulation Resistance Tests

- Dynamometer Tests for Speed, Torque & Efficiency

- Surge Tests

Controller Testing

Our in-house functional tests ensure every controller we build meets regulatory compliance and design specifications. Testing protocols include:

- Bonding Resistance Tests

- Dielectric / Insulation Resistance Tests

- PCB Bring-Up Tests

- RTCA-DO-160 & MIL-STD-461 Tests

- ESS Thermal & Vibration Tests

Record Keeping & Traceability

Our quality management systems ensure comprehensive traceability throughout production, including:

- Lot Traceability for Raw Materials

- Lot Traceability for Purchased Parts

- Production Traceability by Work Order

- Traceability by Serial Number

Test Equipment Quality Control

We maintain strict controls over the calibration and maintenance of our test equipment through:

- Calibration / Recall Database

- Detailed Calibration Histories

- Calibration Schedule Alerts

- Calibration Status Reporting

Control of Nonconforming Material

Identifying and addressing all material non-conformances is integral to our quality management system. Key elements in this process include:

- Internal Material Review Board

- Nonconforming Material Database

- Disposition Procedures

- Failure Analysis & Reporting

“AVEOX guided us through every stage of product development, from concept and prototyping to qualification and full production, ensuring high-quality product and on-time delivery.”

– Motor Designer, Leading Aerospace Firm