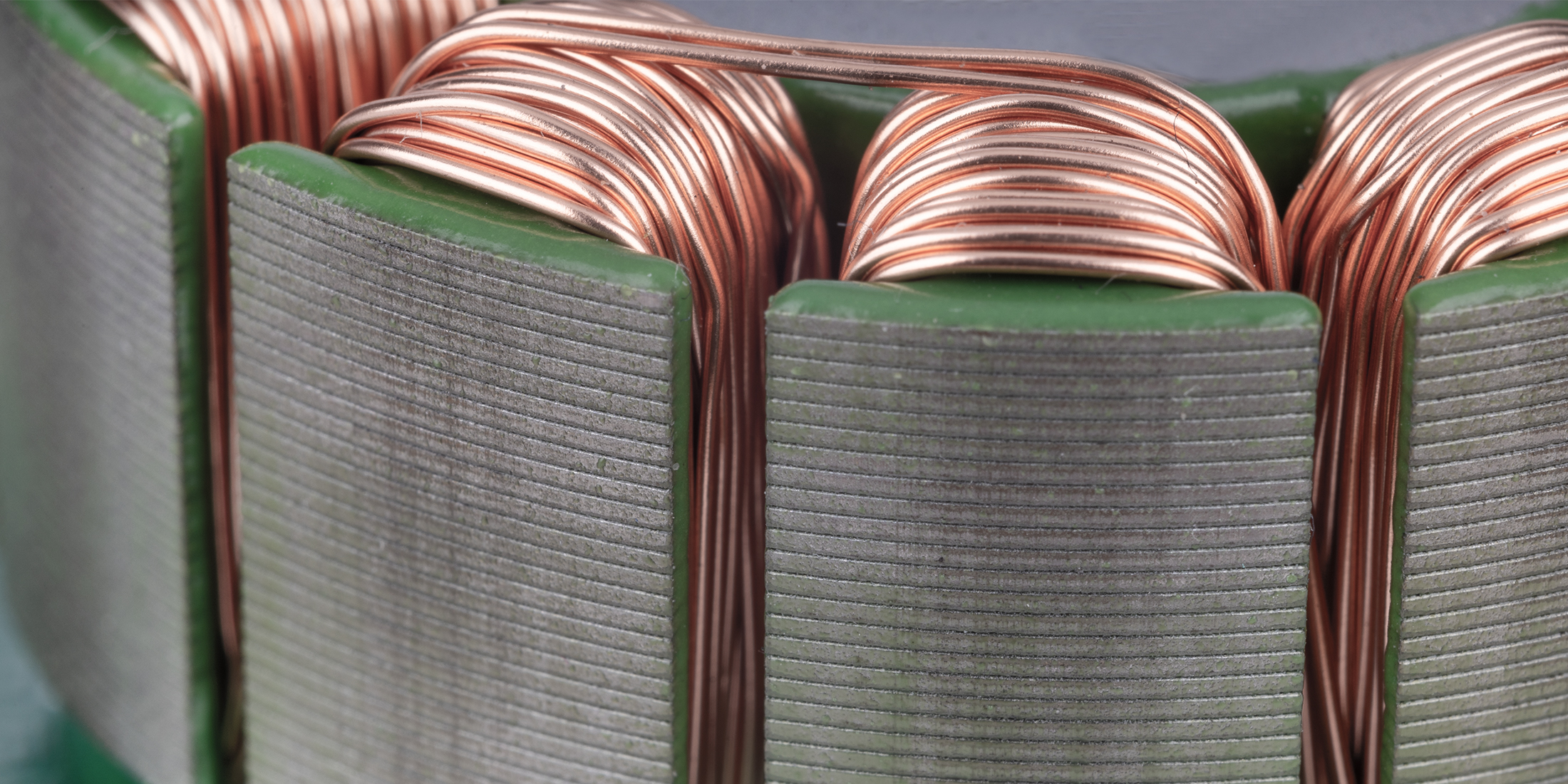

The Power of AVEOX’s Precision Engineering, Technical Expertise & Superior Craftsmanship!

At AVEOX our motor development process begins with Finite Element Analysis (FEA)

Our FEA-driven approach ensures that our designs are optimized for exceptional reliability, efficiency and performance, even in the harshest environments.

The Role of FEA in Motor Design

FEA simulations are integral to our motor development process, enabling us to:

- Refine magnetic flux distribution

- Evaluate mechanical and thermal behavior

- Enhance performance, efficiency and reliability

Key Factors Influencing Magnetic Flux and Motor Efficiency

Several factors affect the magnetic flux distribution and efficiency of motors. Our FEA studies focus on optimizing the following:

- Shape, size and material of permanent magnets

- Rotor and stator configuration

- Iron core saturation point

- Air gap size

- Cogging torque minimization

- Reducing core and copper losses

Enhancing Reliability through Thermal and Mechanical Simulations

To ensure durability and long-term reliability, we utilize advanced thermal and mechanical simulations to:

- Identify critical areas of heat buildup and exploring effective cooling strategies

- Evaluate and mitigate the impact of mechanical stresses such as vibration and shock